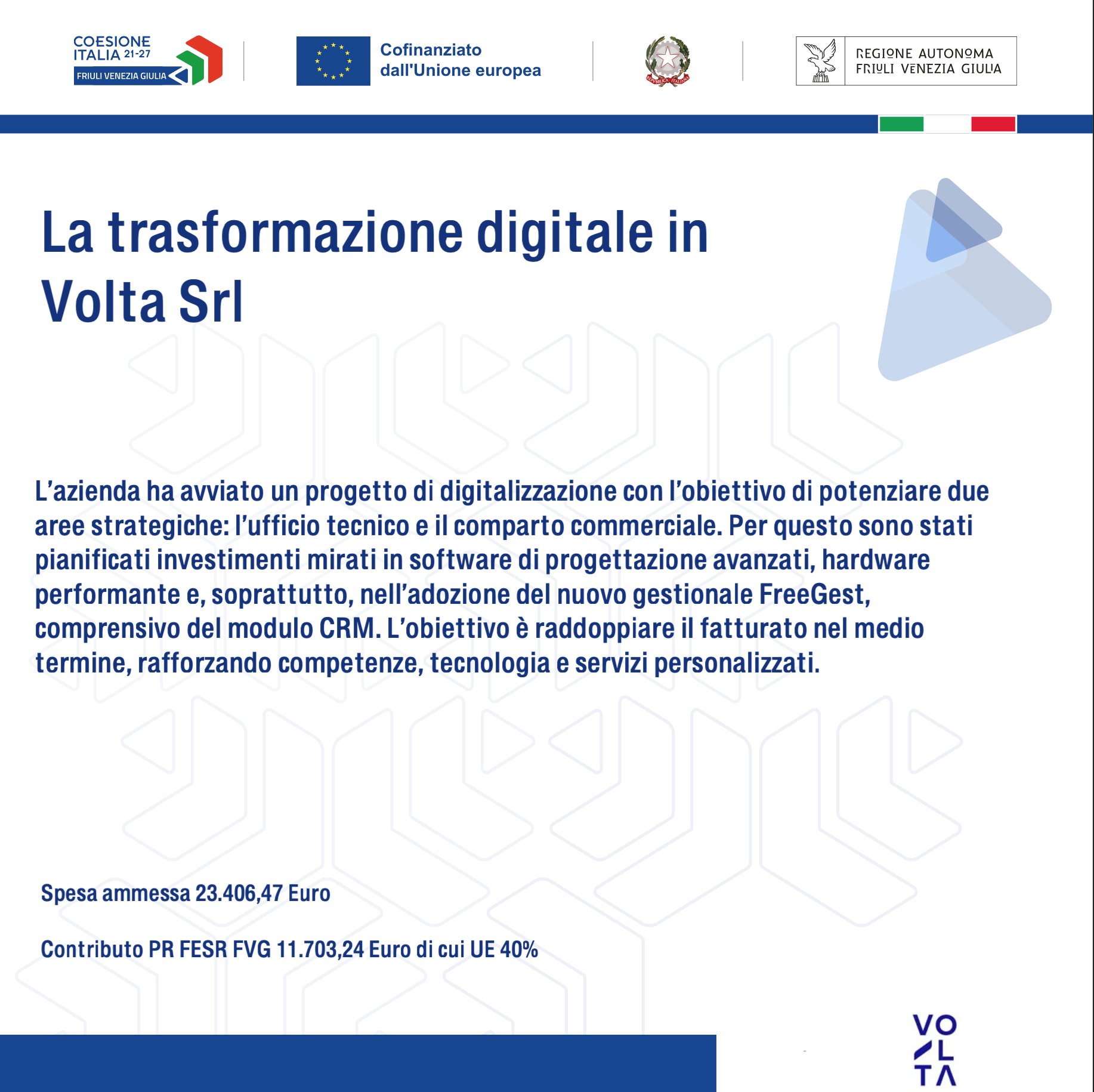

Technical Features Fotonic Twin

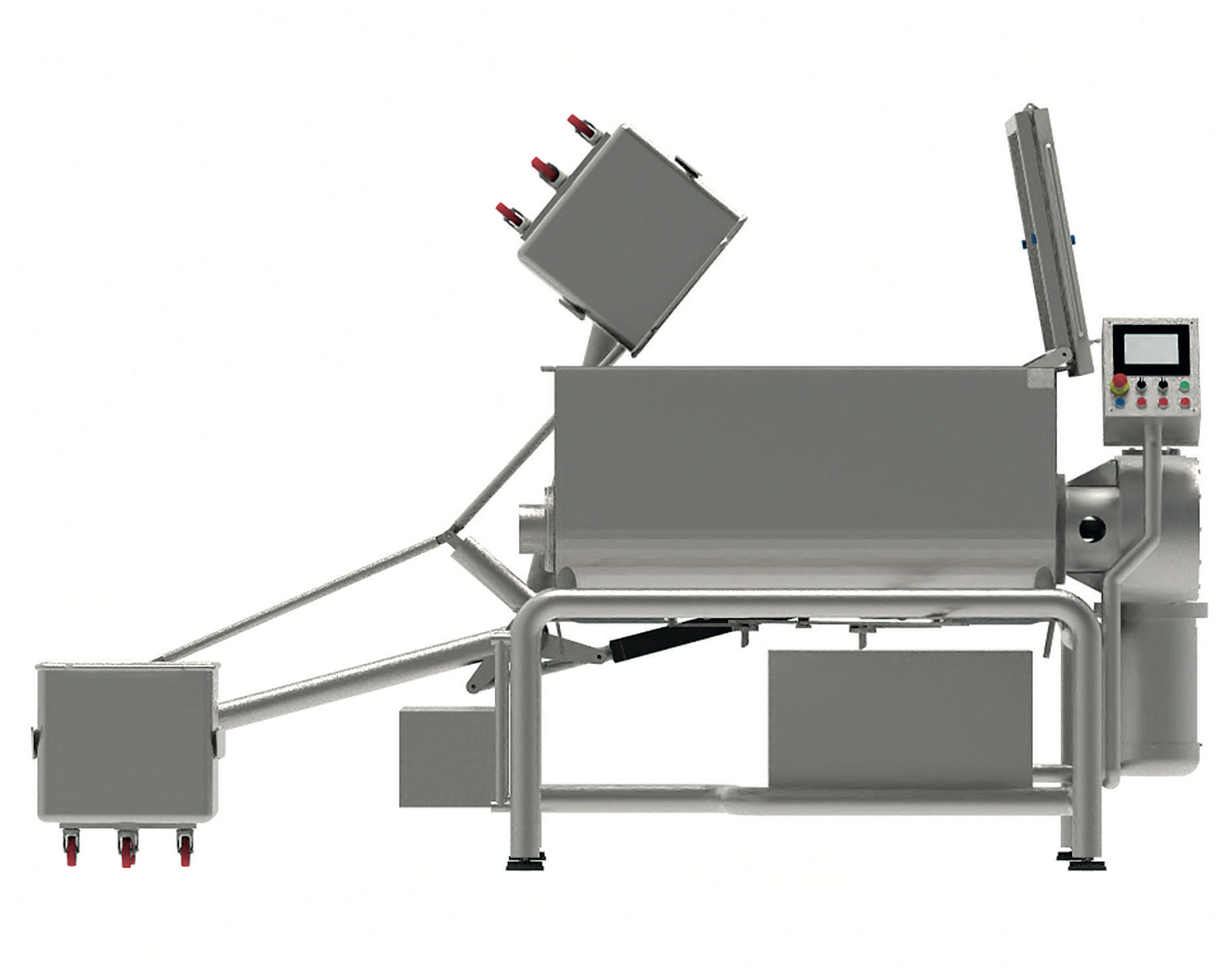

Fotonic Twin is an industrial kneader ideal for the processing of minced meat, ready-made sauces, hamburgers and fresh pasta stuffings.

- Double shaft with intersecting paddles

- 500 lt vat volume

- Delicate blending, preserving the mixture

- Inverted rotation for optimal mixture unloading

- Fine mixture homogenization

- Unloading through sliding double openings

- Minimal maintenance requirements

- Exceptional reliability

- Quickly removable shafts

- Gear motor entirely in stainless steel, IP 69K

- Manually demountable hatches tool-free

- Assistance service provided

- Ideal for integration into production line

- Ceramic micro shot peening

Loading the product

The product is loaded from above by opening the lid, which mounts a metallic net to allow additional ingredients to be added without interrupting the kneading.

The hopper is designed to allow for a combined high capacity and ergonomic shape to simplify the loading process.

Unloading the product

A stick positioned laterally drives the double door unloading system, allowing it to unload into trolleys, bins, or tanks of different sizes.

The round tube frame, and extreme care in limiting angles and interstices, make cleaning the kneader an exceptionally simple, quick, and effective process.

Thanks to the generous dimensions and the use of high-quality components, required maintenance is minimal, ensuring more than optimal reliability over time, as the gearbox comes with a lifetime warranty.

Kneading

The double shaft kneading system featuring perpendicularly oriented paddles makes a homogeneous and uniform mix in very short cycles, preserving the integrity of the product and eliminating the complications of a more prolonged kneading process.

The positioning of the gearbox outside the vat makes the processing safe in terms of contamination risk and protects the mechanical elements from water during cleaning.

Accessories

Manual or automatic double door unloading system

Lateral platform for the operator

Programming system to manage production and automatic functions

Possibility to work in line with meat mincer

Prepared for interconnection with company networks (Industry 4.0) for integration into production cycles"

Taylored Twin

SPECIFIC SOLUTIONS AND DESIGN SERVICE

Our kneaders can be arranged beyond the standard configuration, according to your operational needs.

We design and build automatic loading/unloading systems, allowing Fotonic Twin to be integrated into a production line.

All our machinery can be fitted with automatic cleaning systems, as well as dosage control for additional liquid ingredients.

Sectors of utilization

Sauces and stuffings

Sausages

Hamburgers

Minced meat

Technical data

| Characteristics | Fotonic Twin |

|---|---|

| Vat capacity | 550 liters |

| Rotational velocity | Adjustable via inverter – standard 27 RPM |

| First engine power | 5,5 kW |

| Loading engine power | 0,375 kW |

| Power supply | 400 Volt / 50 Hz |

| Weight of machinery | 300 kg |

| Finish | Ceramic microshot peening |