Techinical Features

The Fotonic series is ideal for the processing of, cereals, flours, vegetables, spices, but also animal feed, pharmaceutical products, cosmetics and confectionary industry.

- Double concentric spiral whisk

- Variable volumes

- Delicate kneading, optimal for fragile products

- Inverted rotation for optimal var unloading

- Prime homogenization of the mixture

- Lowered loading height

- Unloading through sliding automatic opening

- Elevated robustness thanks to generous dimensions

- Quick and easy to sanitize

- Maintenance down to a minimum

- Extremely high reliability

- Customisable for specific requirements

- Maintenance and assistance service included

- Ideal for integration into production line

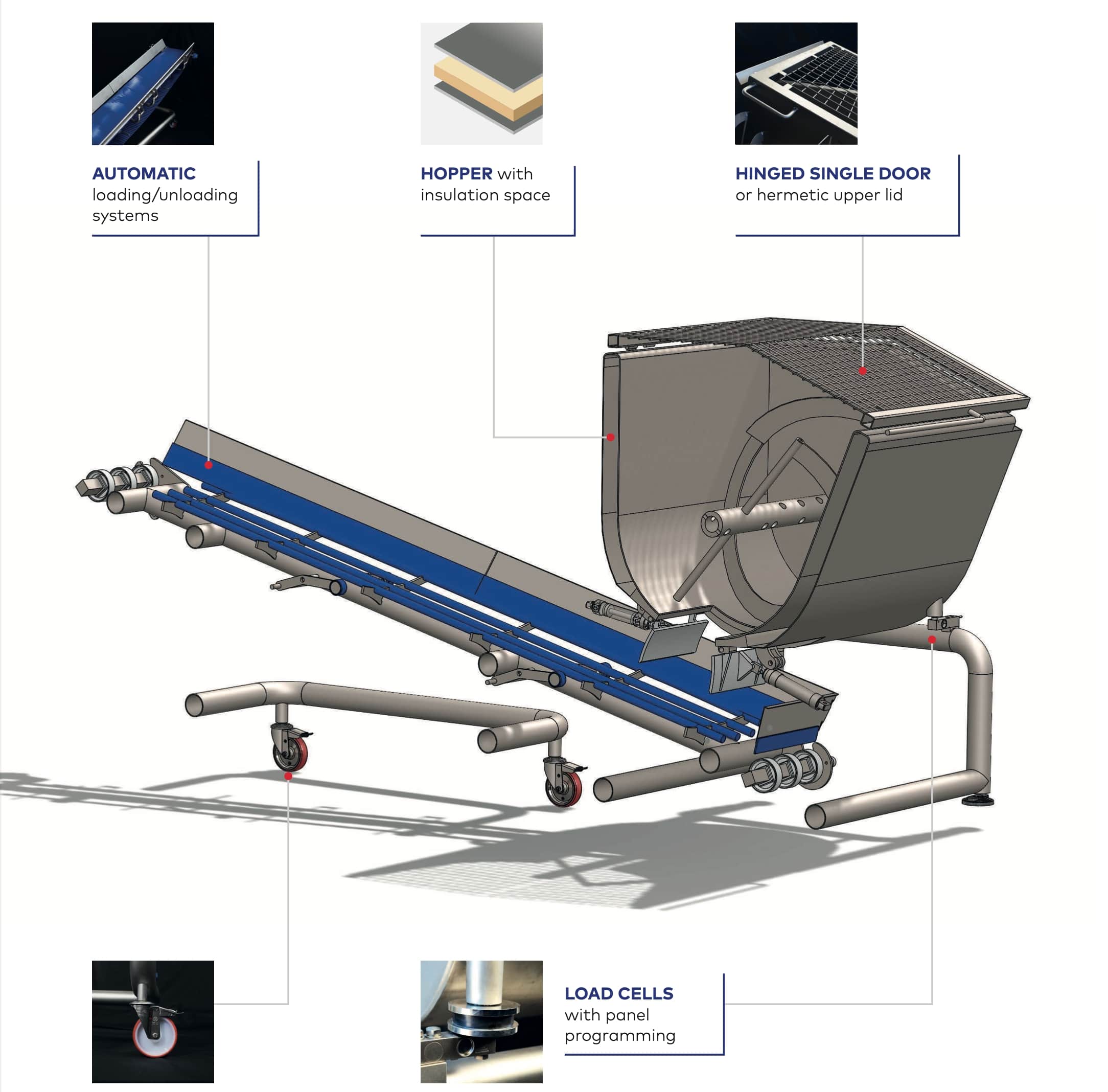

Loading the product

Loading is executed from above. The presence of a metallic net on the lid allows for addition of the ingredients without interrupting the cycle.

The product is immediately weighed at entry by four loading cells which transmit the data to the operator through a touch screen or button interface.

Unloading the product

Unloading is executed by operating the automatic sliding door at the bottom of the hopper. The inverted rotation of the whisk drives the product towards the center, guaranteeing a fully empty vat.

Depending on the application, the loading/unloading systems can be fitted with conveyor belts augers allowing for the mixer to be inserted in a production line.

Kneading

Is executed by a rotational whisk made up of two concentric spirals, guaranteeing a quick and delicate homogenization of the mixture at any loading condition.

Automation is customizable, the program handles acceleration ramps and cycle duration, making for perfect kneading in very short times, limiting therefore the energy cost and time under stress for the ingredients.

Accessories

Different building materials

Lateral platform for the operator

Programming system to regulate production and manage automatic functioning

Gearbox entirely out of stainless steel IP 69K

Provision for interconnection with company networks "Industry 4.0" for integration into production cycles

Taylored Fotonic

SPECIFIC SOLUTIONS AND DESIGN SERVICE

Beyond mixers in different configurations, we offer custom design, production, and implementation services.

Thanks to cooperation with selected providers and many years of field experience, we are able to deliver the best solutions for any specific operational need. Whether the products are fresh, frozen, dry, or wet, we strive for maximum performance and reliability, maintaining a geometric build architecture that is simple and extremely practical during cleaning stages

Sectors of utilization

Food

Animal feed

Chemistry and pharmaceutical

Plastics

Technical data

| Characteristics | Fotonic 2000 E. d.i. | Fotonic 6000 d.i. | Fotonic 12000 d.i. |

|---|---|---|---|

| Material | Stainless steel AISI 304 | Stainless steel AISI 304 | Stainless steel AISI 304 |

| Finish | Ceramic microshot peening | Ceramic microshot peening | Ceramic microshot peening |

| Capacity | 200 Liters | 600 Liters | 1200 Liters |

| Rotational velocity | Inverter regulated 27 RPM | Inverter regulated 27 RPM | Inverter regulated 27 RPM |

| Power supply | 400/220 Volt / 50 Hz | 400 Volt / 50 Hz | 400/220 Volt / 50 Hz |

| Auxiliary circuit | 24 Vac | 24 Vac | 24 Vac |

| Whisk motor power | 1,1 kW | 4 Kw | According to product type |

| Secondary engine | Manual | 1,1 Kw | 1,1 Kw |

| Certification | European Machinery Directive 2006/42/EC | European Machinery Directive 2006/42/EC | European Machinery Directive 2006/42/EC |